With everything enclosed in a protective case, the U-value Measurement System is easy to transport to the site.

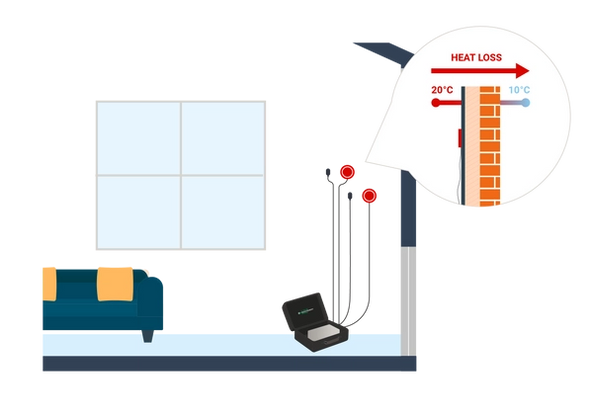

Installation requires that heat flux plates and temperature sensors are temporarily affixed to the building element being measured.

Once configured, the data logger will take readings every few minutes and store them for later data analysis.